Silvering APPLICATIONS

Sphinx® Glass: The Foundation for Exceptional Mirrors

At Sphinx® Glass, we understand that the key to a flawless mirror lies in the smoothly flat glass surface. This is why we take immense pride in manufacturing float glass with an exceptional degree of uniformity and smoothness. This ideal foundation provides the perfect canvas for the application of a high-quality reflective metal layer.

A Spectrum of Applications

Sphinx® Glass offers a comprehensive range of uniformly smooth glass suitable for diverse applications. From enhancing the aesthetics of interior design projects to ensuring optimal functionality in car mirrors, household mirrors, and windowpanes, Sphinx Glass® delivers the ideal raw glass product.

Tailored Solutions for Every Project

Sphinx Glass® empowers designers with the flexibility to specify the perfect thickness for their project’s needs. We supply a wide range of thicknesses starting from 2.7 mm to 6 mm, ensuring you can find the ideal Sphinx Glass® product for flawless mirrors, regardless of the application.

By combining our meticulously crafted float glass with superior silvering techniques, Sphinx Glass® empowers you to create stunning and functional mirrors that elevate any space.

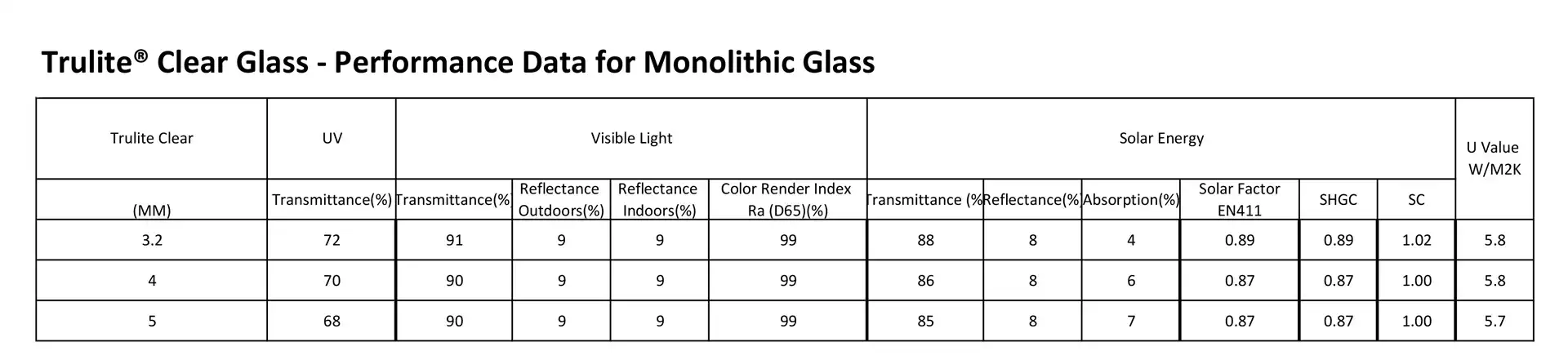

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 %

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

SF = Solar Factor (EN410) also known as g-value.

Color Rendering Index Ra (D65) is a quantitative measure that assesses how accurately the glass transmits or reflects light in a way that preserves the true colors of objects viewed through it, compared to viewing those objects under a natural or standard light source. CRI values range from 0 to 100

“a(D65)” is a standard illuminant that represents average daylight with a correlated color temperature (CCT) of approximately 6500 K. It is used as a reference point in colorimetry

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 % .

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

SF = Solar Factor (EN410) also known as g-value.