Architectural APPLICATIONS

Sphinx® Glass: Mastering the Art of Float Glass Production

Sphinx Glass® takes pride in crafting exceptional float glass using the innovative float process. This advanced technique allows us to achieve perfectly flat and parallel glass surfaces, a crucial factor in delivering exceptional clarity and light transmittance.

The Science Behind the Clarity

The float process begins by pouring molten glass over a bed of molten tin. As the glass flows over this smooth surface, it forms a continuous ribbon with consistent thickness on both sides. This ribbon then travels through a precisely controlled annealing lehr, where the temperature is gradually lowered. This meticulous process relieves any internal stresses within the glass sheet, enhancing its workability for further processing.

Unwavering Commitment to Quality

At Sphinx® Glass, we understand the importance of the annealing stage. We pay meticulous attention to this critical step to ensure optimal results in subsequent processes like tempering, double glazing, lamination, coating, and silvering. Additionally, we employ high-precision online cutting techniques to guarantee that every glass sheet emerges as a perfect rectangle, ready to meet the most demanding specifications.

Sphinx Glass® products are renowned for their exceptional clarity, light transmittance, and dimensional accuracy. This commitment to quality throughout the float glass production process allows us to deliver a superior product for a wide range of applications.

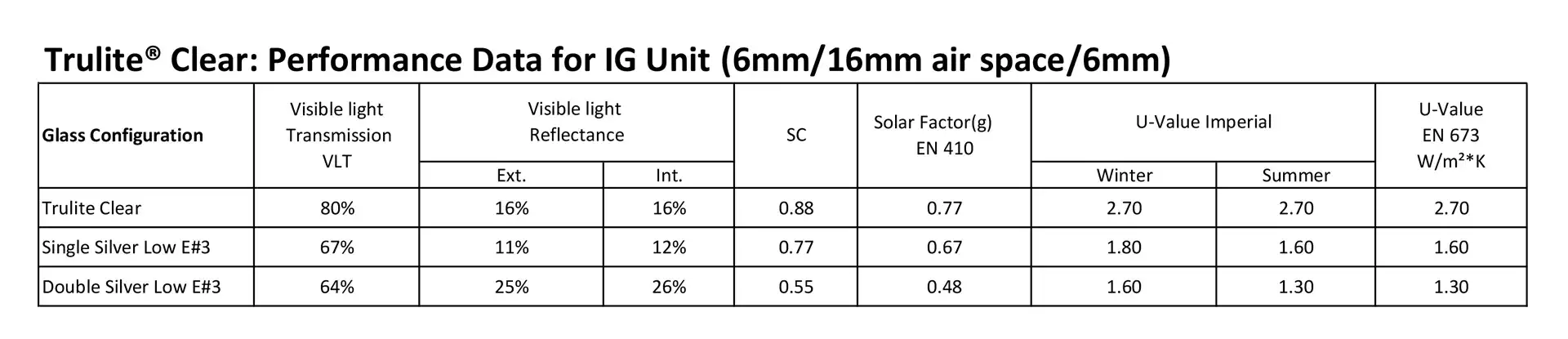

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 % .

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

SF = Solar Factor (EN410) also known as g-value.

Color Rendering Index Ra (D65) is a quantitative measure that assesses how accurately the glass transmits or reflects light in a way that preserves the true colors of objects viewed through it, compared to viewing those objects under a natural or standard light source. CRI values range from 0 to 100

“a(D65)” is a standard illuminant that represents average daylight with a correlated color temperature (CCT) of approximately 6500 K. It is used as a reference point in colorimetry

Data considers 16mm airspace and based on NFRC &EN 673. Other glass thickness is available. See literature or visit www.sphinxglass.com for additional values.

Frameless Applications:

In addition to our various architectural applications, our distinctive glass offers a wide range of frameless applications starting from 8mm thickness. This applies to diverse solar energy, UV, and other applications.

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 %

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

SF = Solar Factor (EN410) also known as g-value.

Color Rendering Index Ra (D65) is a quantitative measure that assesses how accurately the glass transmits or reflects light in a way that preserves the true colors of objects viewed through it, compared to viewing those objects under a natural or standard light source. CRI values range from 0 to 100

“a(D65)” is a standard illuminant that represents average daylight with a correlated color temperature (CCT) of approximately 6500 K. It is used as a reference point in colorimetry

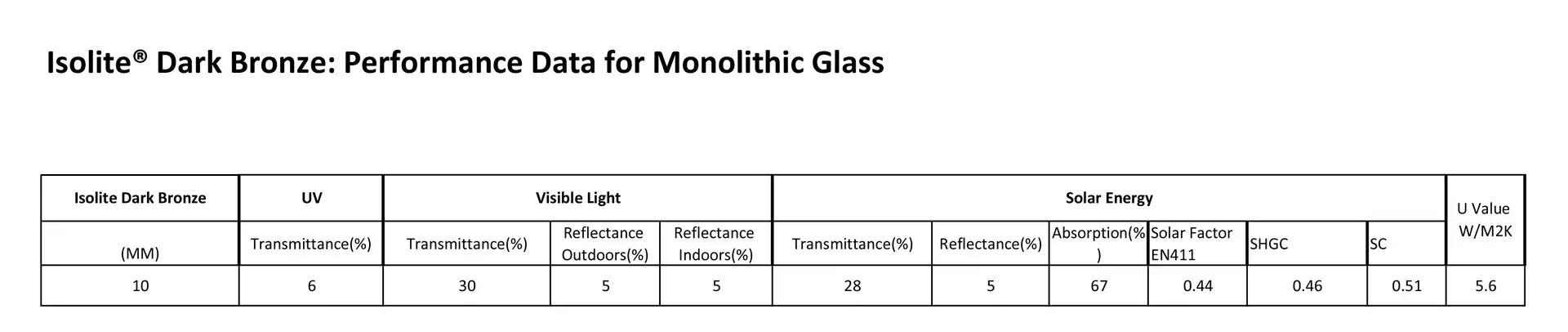

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 %

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

SF = Solar Factor (EN410) also known as g-value.

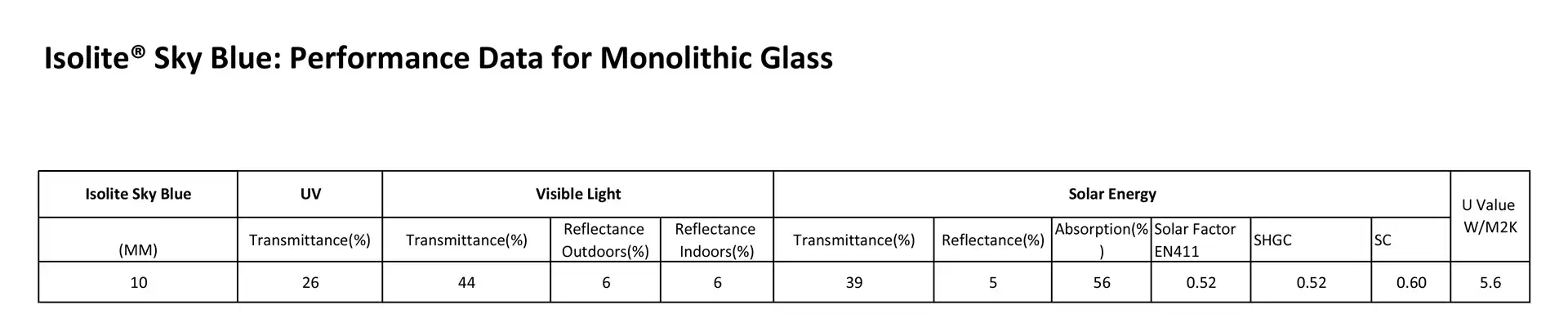

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 %

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 %

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

SF = Solar Factor (EN410) also known as g-value.

Performance data is based on representative samples of factory production. Actual values may vary slightly due to variations in the production process by ±5 %

Tabulated data is based on NRFC methodology using Sommer Global 8.1000 -WINSLT® ASHRAE Software and where noted European methodology using Sommer Global 8.1000 -WINSLT®Standard Software.

SF = Solar Factor (EN410) also known as g-value.