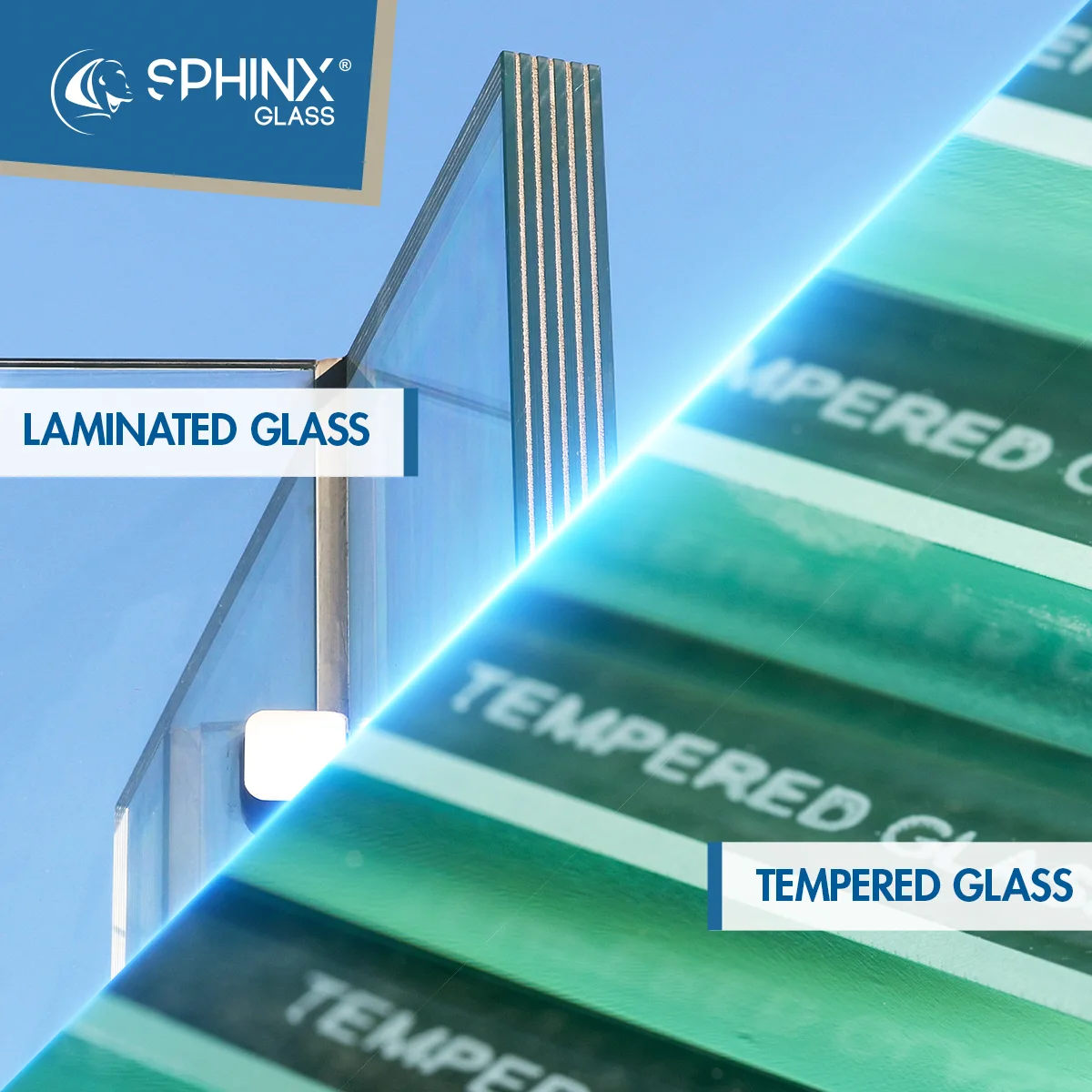

Glass is a versatile material used extensively in construction, automotive, and various industrial applications due to its transparency, strength, and aesthetic appeal. Two common types of glass used for safety and structural purposes are laminated glass and tempered glass. Each type offers distinct advantages and is suited for specific applications based on their unique manufacturing processes and properties.

Introduction

Laminated glass and tempered glass are engineered to enhance safety and durability compared to standard annealed glass. Understanding their differences and applications helps in making informed decisions for various architectural, automotive, and safety-related projects.

History of Laminated Glass and Tempered Glass

Laminated glass has a history dating back to 1903 when it was invented by French chemist Édouard Bénédictus, who accidentally discovered its strength when a glass flask coated with plastic cellulose nitrate did not shatter upon impact. Tempered glass, on the other hand, was developed in the early 20th century to address the safety concerns of standard annealed glass, becoming widely used in automotive and architectural applications.

Uses of Laminated Glass and Tempered Glass

Laminated Glass:

Laminated glass is renowned for its safety features and is commonly used in applications where security and protection are paramount. It is extensively used in:

– Architectural Glazing: Such as curtain walls, skylights, and overhead glazing where safety and resistance to forced entry are crucial.

– Automotive Industry: As windshields provide structural support and prevent occupants from being ejected during accidents.

– Hurricane-prone Regions: Where it offers protection against high winds and flying debris.

Tempered Glass:

Tempered glass is valued for its strength and safety properties, making it suitable for applications requiring resistance to thermal stress and mechanical impact, including:

– Automotive Side and Rear Windows: Where safety and shatter resistance are critical.

– Shower Enclosures and Doors: Providing safety against accidental breakage.

– Commercial Buildings: Used in doors, partitions, and glass balustrades due to its strength and safety characteristics.

How Laminated Glass and Tempered Glass are manufactured

Manufacturing Process of Laminated Glass:

- Assembly: Two or more layers of glass are bonded together with an interlayer usually made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA).

- Heat and Pressure: The assembly undergoes heat and pressure to ensure adhesion between glass layers and the interlayer.

- Lamination: The laminated glass is then placed in an autoclave where heat and pressure further bond the layers, creating a strong composite structure.

Manufacturing Process of Tempered Glass:

- Cutting and Edging: Glass is cut to size and edges are polished to reduce the risk of breakage during tempering.

- Heat Treatment: The glass is heated uniformly to a temperature near its softening point and then cooled rapidly with high-pressure air jets or quenching, creating high surface compression and tensile stress in the center.

- Resulting Properties: Tempered glass becomes approximately four times stronger than annealed glass and breaks into small, blunt pieces upon significant impact, reducing the risk of injury.

Sphinx Glass Manufacturing Laminated Glass and Tempered Glass

Sphinx Glass:

Sphinx Glass is a leading manufacturer of architectural and automotive glass solutions in Egypt, offering a wide range of products designed to meet strict safety and performance standards for laminated and tempered glass, they employ state-of-the-art technologies to ensure product quality and consistency, catering to both local and international markets.